Oil sampling and oil analysisThe purpose of oil sampling is to achieve the highest level of machine performance and reliability by checking the condition and the contamination level of the oil. Based on the oil analysis results benchmarks can be established and machines with critical levels will be identified. |

Where to take an oil sample?

Derive the oil from a preferably upwards pointing pipe with continuous flow to produce a representative sample. Sampling points fitted on the lower perimeter of a pipe tend to allow depositing of

particles in the sampling valve.

A sample taken between the pump and the filter housing of an off-line filter is normally the worst contaminated part of the oil system, and therefore the most representative for the total systems

contamination load..

If no off-line filter system is installed a vacuum type sampling pump is a valid option. In such case the sample should be drawn 10 cm off the lowest part of the tank.

To take an oil sample, the following is required:

- a 200 ml particle free glass bottle

- a five litre open oil container

- a cloth

Please read the following instructions carefully before taking the oil sample.

- Place the oil container beneath the sampling valve.

- Open and close the valve five times and leave it open.

- Flush the pipe by draining one litre into the container.

- Open the sample bottle but avoid contamination to ingress.

- Place the bottle under the oil flow without touching the sampling valve.

- Fill the bottle approximately 80% full.

- Place the cap on the bottle immediately after taking the sample.

- Shake the bottle, empty the oil in the container and repeat filling.

- Close the sampling valve.

- All samples must be clearly marked with reference number, machine reference number, machine make and model, place of sampling, date and oil type/make.

Samples should only be collected with the machine operating at normal working temperature.

When sampling for particle counting the method is very important.

Remember that you can never make a sample any better (cleaner) than the oil in the system, but it is easy to make it worse.

Oil analysis: how to read the data?

As a minimum an oil analysis should include:

- Particle count

- Water content in ppm

- Viscosity

- Acidity level (TAN)

- If the oil additive content is of interest, a Spectral Analysis should be included.

- A 0,8 micron Millipore membrane for sludge detection.

Maximum values:

- Particle count : the 1st rule is that the oil cleanliness should always be adjusted to the cleanliness requirements of the most sensitive component of the system. For example, if the hydraulic system is using servo-vales, a NAS class 6 or better is of upmost importance. In general hydraulic systems should never exceed a NAS 7 class.

- Water: water content is expressed in PPM (parts per million). 1 PPM = 0,0001%. As a rule of thumb water concentration should not exceed 300 PPM.

- Viscosity: the viscosity is expressed in cSt. For hydraulic oil typical oil viscosity are 32 cSt, 46 cSt and 68 cSt mg/KOH gr. For lube oil typical oil viscosity are 220 cSt and 320 cSt. The oil viscosity may vary within a range of 25% up or down the intial viscosity. Meaning that a 46 cSt oil will still be within an acceptable range if the measured viscosity is between 33 and 59 cSt.

- Acidity level – Total Acid Number (TAN): the acidity level or TAN is expressed in mg/KOH gr. Every oil has a maximum TAN value. Ask your oil supplier about your oil maximum TAN level. Typically for hydraulic the maximum level is 1,0 mg/KOH gr. New fresh oil will start around 0,2 mg/KOH gr.

Particle counting standards:

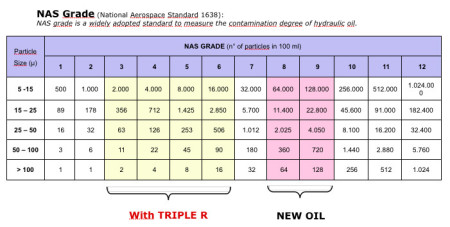

2. NAS 1638 standard:

NAS 1628 is a American standard that references the contamination load based on a breakdown of the different particle sizes for specific particle sizes: 5 to 15 micron, 15 to 25 micron, 25 to 50 micron, 50 to 100 micron, >100 micron. Click to download the NAS 1638 pdf file .

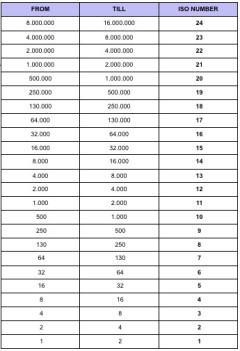

1. ISO 4406 Standard:

The ISO 4406/2000 classification of particle contents was introduced to facilitate comparisons in particle counting. Click to download the ISO 4406 pdf file .

Sudden breakdown in an oil system is often caused by large particles (>14 micron) in the oil while slower, progressive faults, e.g. wear and tear, are caused by the smaller particles (4-6 micron).

This is one of the explanations why the particle reference sizes were set to 4 micron, 6 micron and 14 micron in ISO 4406/2000.

A typical sample contains in every 100 ml of oil:

- 450,000 particles >4 micron

- 120,000 particles >6 micron

- 14,000 particles >14 micron

Introduced in the ISO classification table (on the right), this oil sample has a contamination class of 19/17/14.

The difference is that the NAS gives a detailed breakdown of the different particle sizes lager than 5 micron.

Evaluation of the particle count:

The obtained ISO and NAS code is an indication of the cleanliness of the oil in the system and can be verified in the contamination charts shown above.

Contamination guide for hydraulic and lube oil systems:

- ISO 14/12/10 - NAS 4: Very clean oil, best for all oil systems.

- ISO 16/14/11 - NAS 5: Clean oil, an absolute necessity for servo & high pressure hydraulics.

- ISO 17/15/12 - NAS 6: Light contaminated oil, standard hydraulic and lube oil systems.

- ISO 19/17/14 - NAS 8: New oil, for medium to low pressure systems.

- ISO 22/20/17 - NAS 12: Very contaminated oil, not suitable for oil systems

For every oil-filled system, a cleanliness goal should be specified. This is the basic requirement to insure reliability at the lowest possible cost.

A millipore membrane shows oil degradation if a 0,8 micron cellulose membrane is utilized.

Frequency of analysis:

In the implementation phase of a condition monitoring system, analyses must be made frequently – at least every six months – in order to establish a knowledge data base.

Every oil system should have a log where analysis results are registered.

The logbook must also contain information about oil type, oil changes, break-downs, targeted ISO class code and oil analysis results.